Contact: ☎ 973-405-6248 | ✉ sales@Iron-Powders.com

GRPM5 Sample COA

Graphite powder is very commonly sold alongside iron, copper, and other metal powders because it plays several critical roles in powder metallurgy, metal processing, and industrial applications.

🔧 1) Essential Additive in Powder Metallurgy (Very Important)

Graphite is the primary carbon source used when making steel parts from iron powder.

Why it’s added to iron powder

Steel = Iron + Carbon

Instead of melting steel, manufacturers mix:

- Iron powder

- Small amount of graphite powder

- Lubricants/binders

Then:

- Press into shape

- Heat (sinter)

- Carbon diffuses into iron → becomes steel

Benefits

- Produces strong steel parts without melting

- Precise carbon control

- Lower cost manufacturing

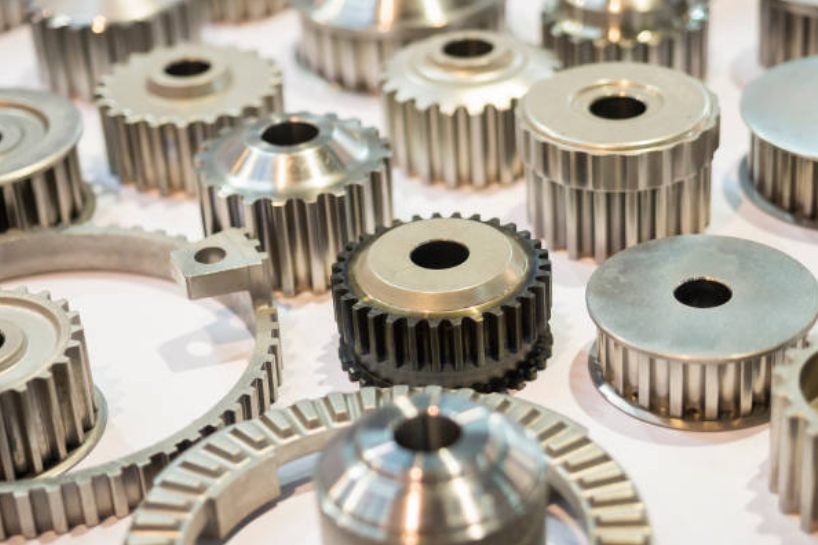

- Used for gears, bushings, automotive parts, tools

👉 This is the #1 reason graphite is sold with iron powder

⚙️ 2) Solid Lubricant (Works Even at High Temperatures)

Graphite’s layered crystal structure lets layers slide easily.

Used to lubricate metal powders during:

- Pressing in dies

- Metal forming

- Machining

- High-temperature operations

- Situations where oil cannot be used

Advantages:

- Works without liquid lubricants

- Stable at high temperatures

- Chemically inert

- Reduces tool wear

🔥 3) Electrical & Thermal Conductivity Additive

Graphite conducts electricity and heat well (though less than copper).

Combined with metal powders to create:

- Conductive pastes

- EMI shielding materials

- Battery components

- Electrical contacts

- Heating elements

🧪 4) Reducing Agent & Metallurgical Processing Aid

Graphite (carbon) can remove oxygen from metal oxides at high temperature.

Used in:

- Sintering atmospheres

- Metal refining

- Foundry operations

- Carbothermic reactions

🧱 5) Improves Machinability of Sintered Parts

Graphite in steel forms structures that:

- Reduce cutting forces

- Improve wear resistance

- Enhance self-lubricating behavior

This is why sintered iron-carbon parts are common in machinery.

⚡ 6) Related Applications with Copper Powders

Graphite is used with copper powders in:

- Electrical brushes (motors, generators)

- Conductive composites

- Sliding electrical contacts

- Thermal management materials

Example: Carbon-copper brushes in motors.

🏭 7) Shared Customer Base

Companies sell graphite with metal powders because the same industries use them:

- Powder metallurgy manufacturers

- Automotive parts makers

- Electrical component producers

- Additive manufacturing (some cases)

- Chemical and materials R&D labs

- Friction materials industry

🧠 Simple Summary

👉 Graphite is not a metal — but it is a critical partner material for metal powders.

Most important relationship:

⭐ Graphite + Iron powder → Steel via sintering

GRPM5 Graphite Certificate of Analysis

Typical COA

Description

| Type: | Natural Graphite |

| Form: | Powder |

| Chemical Class: | C |

| CAS-Number: | Graphite: 7782-42-5 Carbon: 7740-44-0 |

| Product Code: | GRPM5 |

| Lot Number: | CBC071 (from 11039) |

Chemical Analysis

| Test Results % | Min (%) | Max (%) | |

|---|---|---|---|

| Carbon | 95.84 | 95.50 | 100 |

| Moisture | 0.40 | 0.00 | 0.50 |

| Sulfur | 0.14 | 0.00 | 0.20 |

| Surface Area | 11.62 | 9.00 | 15.00 |

Physical Properties

| Apparent Density (Hall) | 0.4 g/cm³ |

Sieve Analysis

| -325 Mesh | 99.99% |

| +325 Mesh | 0.01% |

Microtrac Particle Analysis

| MT10 | 2.75 μm | 10% of particles are smaller than 2.75 μm |

| MT50 | 5.68 μm | |

| MT90 | 10.34 μm | |

| MTMV | 6.27 μm | Mean diameter in micron |

| MTSD | 2.85 μm | Standard deviation in micron |

| MT22M | 99.68% | 99.68% of the particles are smaller than 22 μm |